Kerry Biomatex L ALDC Enzyme – 20g.

฿370.00

In stock

Kerry Biomatex L ALDC Enzyme 20g.

ALDC Enzyme ช่วยลดปริมาณ Diacetyl ในผลิตภัณฑ์ด้วยกระบวนการเร่งปฏิกิริยาเปลี่ยนสารตั้งต้น (α-acetolactate และ α-acetohydroxybutyrate) ที่ทำให้เกิด Diacetyl ไปเป็นสารที่ไร้กลิ่นรส (Acetoin) อย่างรวดเร็ว เพื่อป้องกันรสชาติที่ผิดเพี้ยนและช่วยลดเวลาในถังหมักได้อย่างมีประสิทธิภาพ

- ลดเวลาที่เบียร์จะพร้อมดื่มให้สั้นลง

- ลดการใช้พลังงาน

- เหมาะสำหรับเบียร์ทุกประเภท

- เหมาะอย่างยิ่งสำหรับเบียร์ที่ dry hopping ปริมาณมาก เพราะช่วยลดปริมาณ Diacetyl เนื่องจากปฏิกิริยา Hop Creep

- เพิ่มประสิทธิภาพและกำลังการผลิต

*Diacetyl คือสารประกอบอินทรีย์ที่เกิดขึ้นระหว่างกระบวนการหมัก มีกลิ่นรสคล้าย เนย ป๊อปคอร์น และมี flavour threshold ที่ต่ำมาก (0.04ppm in Lagers) นั่นหมายถึง มีปริมาณ Diacetyl อยู่ในผลิตภัณฑ์เราเพียงเล็กน้อย ก็รู้สึกถึงรสของมันแล้ว

Biomatex L is an alpha-acetolactate decarboxylanase (ALDC) produced enzyme derived from a select strain of Bacillus subtilis.

Developed for its ability to break down alpha acetolactate, the precursor to diacetyl, Biomatex L is used in brewing applications to prevent off-flavours and expedite maturation time.

Simply add Biomatex L to your wort before fermentation or during transfer to reduce diacetyl compounds, ensure quality, and turn more beer more quickly.

Dosage: Add 0.5 to 5g/hl, or 0.7 to 5g per barrel of wort.

Benefits

- Reduces Diacetyl* content in beer.

- Shorter and more consistent maturation times.

- Reduces energy consumption and drives sustainable brewing.

- Improves fermentation and maturation vessel utilization and turnaround time.

- Suitable for all types of brewing processes.

- Suitable for dry hopping as it reduces diacetyl during Hop Creep.**

- Increases and optimizes production capacity.

Biomatex L (ALDC)

An enzyme solution for diacetyl control in beer during fermentation.

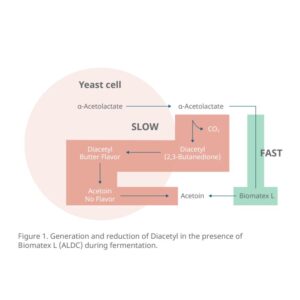

How does Biomatex L (ALDC) work?

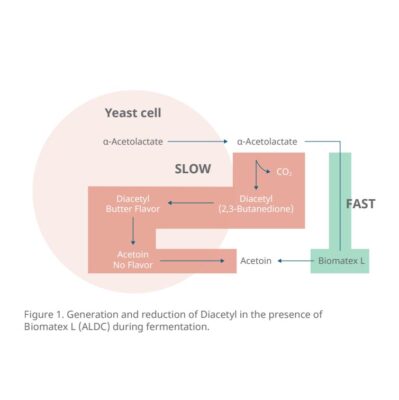

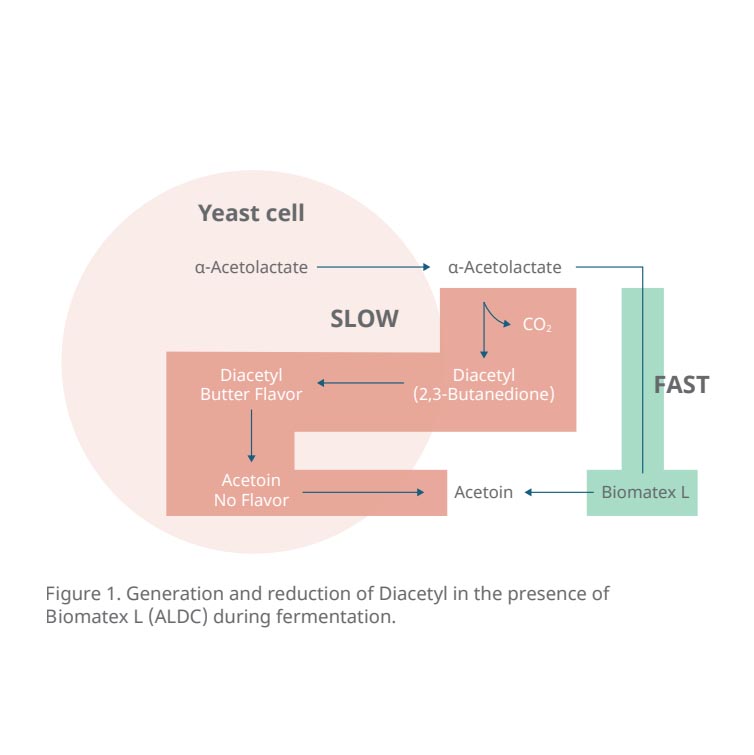

Biomatex L (ALDC) converts α-acetolactate and α-acetohydroxybutyrate produced during fermentation directly into the flavorless compounds acetoin and 2,3-pentanediol, respectively.

This prevents the formation of Vicinal Dikentones in beer, which even at very low levels give a strong ‘buttery’ off flavor to beer.

During normal fermentation, this reaction is relatively slow compared to the reaction speed of Biomatex L (ALDC)

Application Dosage

- Biomatex L (ALDC) can be added before fermentation and maturation.

- Typical dosage rate is 0.5–5.0 g/hL (5–50 ppm)

- Biomatex L (ALDC) is best added to cold wort during wort cooling in the fermenter before starting fermentation.

- If required, Biomatex L (ALDC) can be added, at the same dose rate, post fermentation (>50°F), to rescue beers with high diacetyl levels and prevent prolonged storage in maturation.

- Post fermentation, it can be added after purging the dead yeast and roused with carbon dioxide for 5–10 minutes.

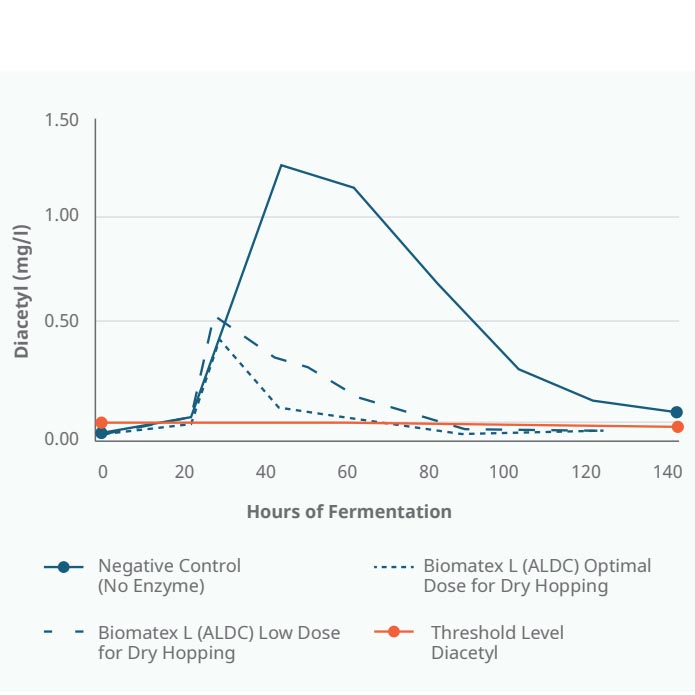

Application Results

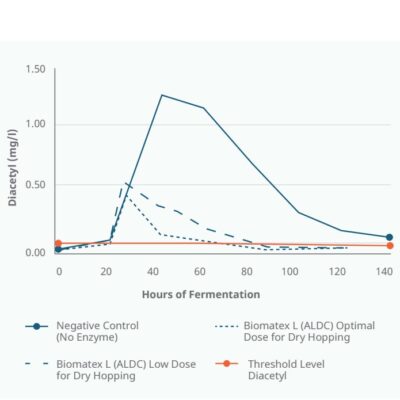

- Biomatex L (ALDC) reduces levels of both diacetyl and 2,3-pentanedione during fermentation of short consistent maturation periods.

- Biomatex L (ALDC) is reliable and robust in most brewing protocols and process conditions and is easily applied at the start of fermentation.

Storage and Shelf Life

- Biomatex L (ALDC) should be stored in cool, dry conditions. Store product at 36–50°F (2–10°C) and away from direct sunlight.

- The enzyme will provide optimal activity if stored as recommended and used within 24 months.

- Do not allow to freeze.

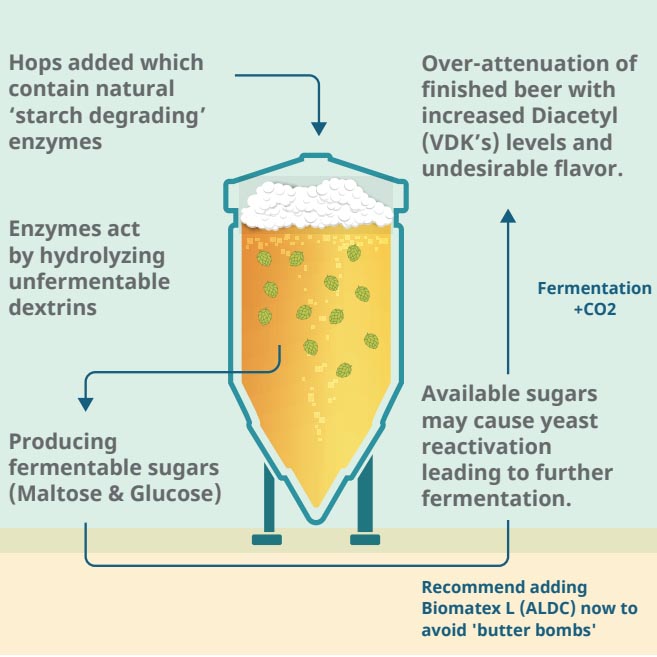

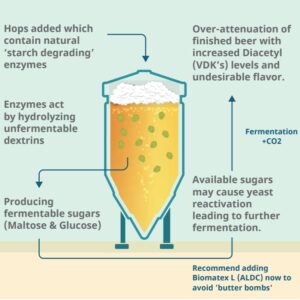

Biomatex L (ALDC) for Hop Creep

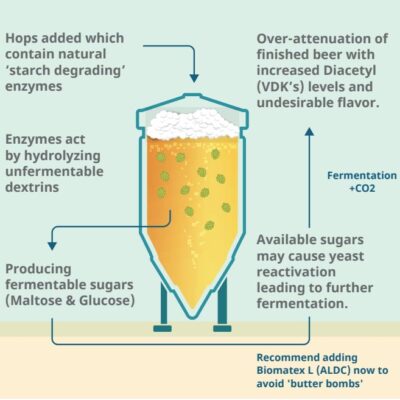

Biomatex L (ALDC) works to reduce excess amounts of Diacetyl produced during dry hopping or hop creep.

Hop Creep is an additional fermentation in dry hopped beer initiated by naturally present hop-derived starch degrading enzymes.

These enzymes hydrolyze unfermentable dextrin into fermentable sugars when added during the dry-hopping process, which can potentially cause re-fermentation and reactivation of yeast, producing diacetyl.

This process can increase production time because beer can be ‘out of specification’ for diacetyl levels, alcohol

content or residual sugars.

Application

- Biomatex L (ALDC) is added at onset of fermentation and additionally before dry hopping to obtain maximal diacetyl reduction.

- (Enzyme may lose activity due to low pH after fermentation so recommend additional dose).

Dosage

- Biomatex L (ALDC) at start of fermentation 0.5-5.0 g/hL (5-50ppm).

- Prior to dry hopping, Biomatex L (ALDC) can be added. Exact dose will depend on the process conditions.

Benefit

- Reduce amount of Diacetyl after dry hopping.

- Used in different styles of dry hopped beer e.g. IPA & Low Alcohol level beer.

- Maintain beer in specification.

- Increase efficiency and capacity.

- Reduces maturation time.

- Reduces risk of ‘diacetyl bombs’.

| Weight | 140 g |

|---|

Be the first to review “Kerry Biomatex L ALDC Enzyme – 20g.” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.