ตู้หมัก RAPT Fermentation Chamber (Temperature Controlled) KL15813

฿27,800.00

Only 2 left in stock

Only 2 left in stock

KL15813 RAPT Fermentation Chamber (Temperature Controlled)

ตู้ควบคุมอุณหภูมิที่สามารถใช้งานได้หลากหลาย เพราะมีทั้งสามารถทำความเย็นและทำความร้อนได้ในตัวเดียว อุณหภูมิที่ควบคุมได้ ตั้งแต่ -2C – 50C นอกจากนี้ยังติดตั้ง RAPT Temperature controller ในตัว ทำให้สามารถควบคุมสั่งการได้ผ่าน RAPT Portal สร้าง Schedule การหมักได้อย่างง่ายดาย นอกจากนี้ยังทำงานร่วมกับ RAPT Pill ซึ่งสามารถนำค่าอุณหภูมิที่วัดได้จาก RAPT Pill มาเป็นข้อมูลในการปรับอุณหภูมิภายในตู้อีกด้วย นอกจากจะใช้เป็นตู้หมักอาหารเครื่องดื่มได้หลากหลาย ยังใช้บ่ม หรือเป็นตู้แช่ไวน์ เก็บไวน์ เอจเบียร์หรือเครื่องดื่มต่างๆ ได้อย่างดี

RAPT Pill – Hydrometer & Thermometer (WiFi & Bluetooth) – KL20596

RAPT fermentation chamber has been designed to heat and cool your entire fermenter.

This is the ideal scenario as the whole fermentation vessel is placed in a temperature controlled environment which gives you the most even temperature and most precise control of your fermenter.

From -2°C up to 50°C all at the touch of your fingertips!

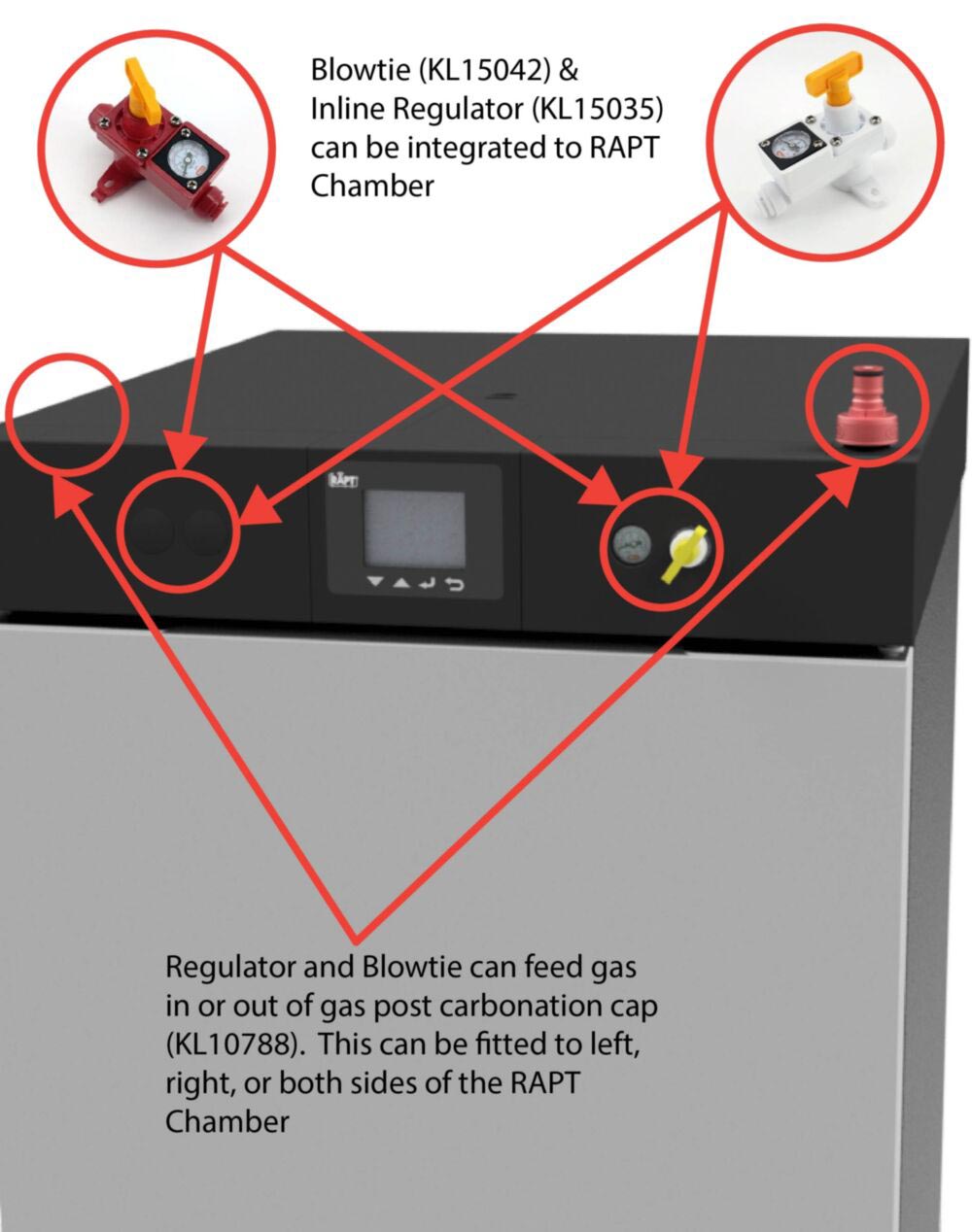

The control panel comes complete with an integrated colour TFT screen, Spunding Valve and CO2 gas integration.

Example combination Inline Regulator with an integrated gauge and a Gauge integrated BlowTie unit to the other side to regulate residual pressure in your fermenter.

The 4 button colour display conveniently shows a log of historic temperature graphs, allows you to start, set/stop temperature profiles and gives you access to other critical information for that particular fermentation.

For more accurate readings of the core temperature of your fermenter.

We highly recommend using a thermowell like our 60cm duotight thermowell with the 2m probe extension for the RAPT Fermentation Chamber.

What is RAPT?

RAPT is a dedicated Internet of Things (IOT) Hub for fermentation logging and control.

It’s a free service whereby any RAPT enabled product can both log and store data to the hub where you can conveniently access this data.

The RAPT hub can also allow you to control your devices remotely giving you absolute control of the device irrespective of where you are.

The RAPT portal enables you to make complex temperature profiles that involved different temperature settings over time meaning you can start/run a temp profile giving you a set and forget experience.

The RAPT portal also controls the alert/notification process for you so you can receive email notifications in the off instance that something doesn’t go to plan.

RAPT Fermentation Chamber Specifications:

Integrated Heating: 50watt Heating Power

Cooling Capacity: 300watt Cooling Power

Max Power Consumption: 225 Watts

Refrigerant: r600a

Connectivity: WIFI (802.11) and Bluetooth

Temperature accuracy: +/- 0.1C

Temp Resolution: 0.1C

Integrated Screen: 2.8inch (diagonal) 320 x 240 Colour LCD TFT Active Matrix

RAPT Fermentation Chamber External Dimensions:

Width: 540mm

Depth: 610mm

Height: 1760mm

RAPT Fermentation Chamber Internal Dimensions:

Width: 440mm

Depth: 500mm

Height: 1300mm

To see the dimensioned drawings on this part click here.

Why buy an insulated fermentation chamber over a glycol chiller?

Typically in the past, some customers have needed to resort to glycol chillers to chill fermenters but this represents several issues:

1. Glycol chillers often require a very cold liquid to enter into a fermenter causing an excessively cold part in the fermenter core.

2. Glycol chillers consume significant amounts of power and in most instances more than double what this chamber would consume.

3. Glycol chillers often result in spilling sticky glycol especially when hoses are connected and disconnected to the fermenter.

4. Glycol chillers generally require penetrations through the walls/lid of the fermenter making the fermenter less sanitary and requiring more cleaning. “who needs that!”

5. Often fermenters are not made with sufficient insulation. So when using a glycol chiller much of the chilling is lost which is not only power inefficient but the customer ends up with a large temperature gradient. This temperature gradient can result in convection currents in the fermenter that make it difficult for yeast and other solids to settle out of suspension. So clarification of the beer takes significantly longer.

6. Many glycol chillers and fermenter combinations do not have sufficient power or are not well enough insulated to cool to sub-zero temperatures. So crash chilling is not possible.

This is a significant compromise to a temperature-controlled solution and also results in less ability to clarify the finished beer.

For these reasons KegLand has developed the worlds first dedicated RAPT enabled fermentation chamber that can cool down to -2C and heat up to 50C even in hot and cold weather.

For more information: KL15813 RAPT Fermentation Chamber

Looking for a Kegerator?

| Weight | 21000 g |

|---|

Brand

RAPT

Be the first to review “ตู้หมัก RAPT Fermentation Chamber (Temperature Controlled) KL15813” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.